��ˮ������ֹˮ����������ͨ���֮����

������Ĥ��ȾɫĤ�������������𣬾ͷ�����ӿ������20��ķ��Ʊ�ã��ж���������㱡������Ĥ�������¸���˿��Ϯ���˻���һ����һ����ĤҲ��ȾɫĤ������Ĥ���մ�Ĥ����������Ĥ......���ֲ������������ſؽ���......���ֹ��պھ�Ĥ����ɹĤ���Ų�Ĥ......�������㣬һ���������������ϰ��Ǯ�����ƶ���Ϊȫ��Ĥ������������20��**��չ������ѱ䡢ת��ʱ�ڡ�Ĥ����ʹ�ڡ�Ĥ��Ŀ�ʼ��ҵ���µĿ�������ɭ����ģ���2016̫��Ĥ�߶ˡ������������̫��Ĥϸ������ĸ߶ˡ���ʶ������ҵ���⣬��Ҫ�����ҵʹ�㣬��������ı����ҵ���ƾ֡����г��仯�;�������Ĥ�硱ʹ���ܲ����۸�֮ʹ��û�У�ֻ�и���Ʒ��֮ʹ����Ᵽ�ά*Ȩ�հ�֮ʹ������ǰ�����أ�4s�Դ�Ʒ������������ʽ���ն˵���Ϊ��������֮ʹ��ͨ·��Ƭ�����������Ի���ӯ�ձ�����......���ʲô���⣿����۸�֮ʹ--�߳��۸���Ծ�����̶�����Ʒ��֮ʹ--����������ˣ�Ʒ��������֮ʹ--����ɹ���ת��������

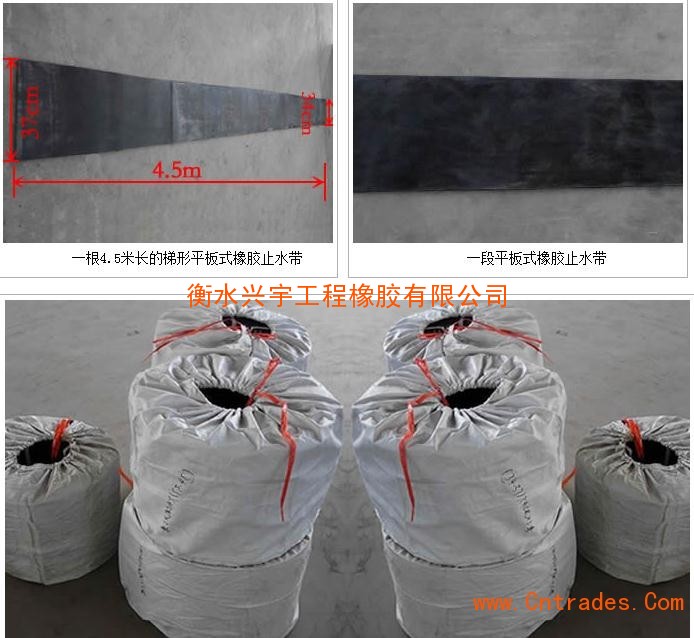

����ʽ��ֹˮ���ڹ����ڶ�������ˮ�����̵ĵ���Ӧ�ã��ڽ��������л��������������ڲ���������ע�������ڵػ��ı��Σ��������¶ȵı仯����Ļ���������������ԭ��������ʩ���졢�����졢�����졢���η죬����Щ�촦���밲װ��ֹˮ������ֹˮ����©���⡣����ʽ��ֹˮ����Ҫ���ڻ������ֽ�ʱ����ʩ���켰���η�����������ṹ��Ϊһ��Ļ������̣��������ʩ����������ˮ�ɲۡ���ˮ�ӡ���Һ������ȡ�����ֹˮ����װʱ��������ֻ�������עʽ�в��ֻ�ȫ�������ڻ������У����������������ǵ�ʯ�Ӻ������ĸֽ�ͷ��������������ǿ�ȱ�����ǿ��3-5����ֹˮ��һ�������ƻ�ʱ������ܴ��������ѿھͻ�����������ֹˮ����λ�ͻ����������У�Ӧע�ⶨλ�ͽ���ѹ��������ֹˮ�������ơ�

Back stick type rubber sealing strip used in many domestic construction, water conservancy project, in construction engineering or bridge construction due to continuous casting, or as a result of the ground deformation, or concrete expansion caused by the variation of temperature and cold, need to he construction joints, expansion joints and settlement joints, deformation joint and in these joints must be installed to prevent the rubber sealing bring water leakage problems. Back stick type rubber strip is mainly used for cast-in-place concrete when in construction joints and deformation joints and concrete structure has become one of the basic engineering facilities, such as tunnels, culverts, dams, aqueducts, liquid storage structures etc.. In the rubber waterstop, if it is found that the concrete pouring process in all or part of pouring buried in concrete, there are many sharp stones and sharp head reinforced concrete, the tear strength of rubber and plastic tensile and low 3-5 times, once the waterstop punctured or torn, without external force cracks will expand, so the waterstop itioning and concrete pouring process, should pay attention to itioning method and pouring pressure, so as to oid the water stop punctured.

����ʽ��ֹˮ����һ������Ȼ������ֺϳ���Ϊ��Ҫԭ��,���Ӹ��������������,��������������ѹ�Ƴ���.��ֹˮ���������ĸߵ��Ժ�ѹ�������Ե��ص㣬����ʽ��ֹˮ���ڸ����غ��²������Ա��Σ��Ӷ�����Ч�����ܷ⣬��ֹ���������©ˮ����ˮ���������õ�ֹˮ����Ʒ��������ֹˮ����λ�ͻ����������У�Ӧע�ⶨλ�ͽ���ѹ��������ֹˮ�������ƣ�Ӱ��ֹˮЧ������ʩ����λ���о���ע���������£�

Back stick type rubber strip is a kind of natural rubber and synthetic rubber as the main raw material, and the filling material mixed with various additives, through plasticizing, mixing, pressing and molding. The rubber sealing strip is the rubber high elasticity and compression deformation characteristics of back stick type rubber sealing strip to generate elastic deformation in under various loads, so as to effectively prevent water sealing cushion construction Water Leakage, seepage and damping belt products. Therefore, in the process of water stop itioning and concrete pouring and tamping, attention should be paid to the itioning method and pouring pressure, so as to prevent the water stop being punctured and affect the sealing effect, and the specific precautions for construction units are as follows:

��ˮ������ֹˮ������ ��ʱ���еĽ�ͻȻһ�ܣ�ȫ������߽С���������Ѫ�������Ĺ��ż��зɴ̹�ȥ��һ���¡¡֮���������˶���һ���������Ѫ�⾹���˲��١�һ��ֻ������һ��İ�ɫ���������һ����Ŀ�����ޱȣ������Ǹ��������ꡣ����ת�ۼ䣬Ѫ����Ҫ��£Ȭ�������ӡ�ֻ�����һ������ı�������Ȼ���������㹻�����ǣ���ݺݵij�������˵����������˵����Ȼû����ȫ�����ɹ�������ƾ���Լ����������ԣ�Ҳ���ˡ�������������ӵ�ͬ�鶼����������δ���������������������ˣ����˵�������ɫһ�䡣�����Ǹ�����Ը���ϻ��ĺ����������ܷ����Ĺ�����

��ʱ���еĽ�ͻȻһ�ܣ�ȫ������߽С���������Ѫ�������Ĺ��ż��зɴ̹�ȥ��һ���¡¡֮���������˶���һ���������Ѫ�⾹���˲��١�һ��ֻ������һ��İ�ɫ���������һ����Ŀ�����ޱȣ������Ǹ��������ꡣ����ת�ۼ䣬Ѫ����Ҫ��£Ȭ�������ӡ�ֻ�����һ������ı�������Ȼ���������㹻�����ǣ���ݺݵij�������˵����������˵����Ȼû����ȫ�����ɹ�������ƾ���Լ����������ԣ�Ҳ���ˡ�������������ӵ�ͬ�鶼����������δ���������������������ˣ����˵�������ɫһ�䡣�����Ǹ�����Ը���ϻ��ĺ����������ܷ����Ĺ�����

1�����ý�����ʽ��ֹˮ����ʱ��¶����ɹ����ֹ���ܣ�������Ⱦ��ǿ�Ļ�ѧ�� 2���������ʩ���У���ֹ��е���ֽ�����ֹˮ����

1, not to back affixed rubber waterproof tape for a long time exure to the outside, to prevent rain, do not contact with polluting chemicals. 2, in the transportation and construction, to prevent mechanical, steel damage water stop.

3��ʩ���У�ֹˮ������ɿ��̶��������ڽ�ע������ʱ����λ�ƣ���ֹ֤ˮ���ڻ������е���ȷλ�á� 4��ͨ�����й̶�ֹˮ�����У����ø��Ӹֽ�̶���ר�ÿ��߹̶���Ǧ˿��ģ��̶��ȣ����贩��ʱ��ֻ��ѡ��ֹˮ���ı�Ե��װ�������������������֡�

3, in the construction process, the water stop belt must be reliably fixed, to oid displacement when pouring concrete, to ensure the correct ition of the water stop belt in concrete. 4, usually fixed waterstop are: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template, such as perforation, can only choose the installation area on the strip edge, not to damage other parts.

��ֹˮ�����������������ǵ�ʯ�Ӻ������ĸֽ�ͷ���������Ϻ���ǿ�ȱ�����ǿ��3-5����ֹˮ��һ�������ƻ�ʱ������ܴ��������ѿھͻ�����������ֹˮ����λ�ͻ����������У�Ӧע�ⶨλ�ͽ���ѹ��������ֹˮ�������ƣ�Ӱ��ֹˮЧ��,����ע����������:

The rubber sealing belt has many sharp stones and sharp head reinforced concrete, the tear strength of rubber and plastic tensile and low 3-5 times, once the waterstop punctured or torn, without external force gap will expand, so the waterstop itioning and concrete pouring process, should pay attention to itioning method and pouring pressure, so as to oid the water stop is punctured, influence the sealing effect, the specific considerations are as follows:

1 ֹˮ�����ó�ʱ��¶����ɹ����ֹ���ܣ�������Ⱦ��ǿ�Ļ�ѧ��

1 the water stop belt should not be exed to the outside for a long time to prevent rain, and do not contact with strong polluting chemicals.

2 �������ʩ���У���ֹ��е���ֽ�����ֹˮ����

2 in the transport and construction, to prevent mechanical, steel damage, water stop belt.

3 ʩ���У�ֹˮ������ɿ��̶��������ڽ�ע������ʱ����λ�ƣ���ֹ֤ˮ���ڻ������е���ȷλ�á�

3 in the construction process, the water stop belt must be reliably fixed to oid displacement when pouring concrete, and ensure the correct ition of the water stop belt in concrete.

4 �̶�ֹˮ�����У����ø��Ӹֽ�̶���ר�ÿ��߹̶���Ǧ˿��ģ��̶��ȣ����贩��ʱ��ֻ��ѡ��ֹˮ���ı�Ե��װ�������������������֡�

4 fixed strip method: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template, such as perforation, can only choose the installation area on the strip edge, not to damage other parts.

5 �û�����ʱӦ���ݹ��̽ṹ�����ͼֽ����ò�Ʒ���ȣ����ͽṹҪ��ͼֽ˵���������ڹ����н�ֹˮ�����ӳ����壬�������ֳ�����ʱ���ɲ��õ���Ȱ���ճ�ϻ���ճ��(��ֹˮ��)��(����ֹˮ��)��.

5 user orders should be based on the engineering structure design drawings, calculate the length of products, he special structure drawings and specifications, try to connect into a whole band in the factory will stop, if necessary in the field of connection, can use electric heating plate vulcanization bonding or cold bonding (rubber waterstop) or welding (plastic waterstop) method.

��ˮ������ֹˮ��������λ�������Ӧ��ͨ���еı���Ԫ�⡣

��ֹˮ������������ֹˮ��;�ֱ���ֹˮ�������м亸ֹˮƬ�����ģ�崦����λƬ,���ڸֱ���ֹˮ��Ҫ������,��λƬֻҪ�ι̾Ϳ�����,��λƬ��ģ��Ҫ��һ�������ֵľ���,��֮������ϻ���ľ�ʵ�Ƭ����ģ����,����ݸ˺���ɰ����ƽ�������ֹ����ټ� �����ö�һ����ݸ���������ݸ�,��ģ����Ժܷ���IJ��¡�

The rubber sealing strip is used for sealing; steel edged rubber water stop outside the middle rubber waterstop welding near the template at the welding itioning piece, the steel edged rubber water stop full welding requirements, as long as the firm itioning piece can, itioning distance template to one to two cm distance, plastic or wooden pads plus this. After stripping out, cut off after the mortar filled with micro expansion screw. There are kinds of domestic rare connection screw rod is a little shorter, after stripping can be easily disembled.

��ֹˮ�����ڻ�������ע�в��ֻ�ȫ����ע�������С��ڽ����������ǰ��Ҫʹ���ڽ��沿λ����ƽչ����ͷ����ճ�ӽ��̣������ʵ�������ֽ���������������λֹˮ����ʹ������������õĽ�ϣ�����Ӱ��ֹˮЧ����

Rubber sealing strip is partially or wholly poured into concrete in the course of concrete pouring. Before pouring concrete buried first kept flat on the interface at the joint part, adhesive fastening, with appropriate force sufficient to locate the concrete pouring, the shock of waterstop, combining the concrete with good sealing effect, so as not to affect the.

��ֹˮ��ʩ��ע��������ʩ���У����ڻ��������������ǵ�ʯ�������ĸֽ�����ڽ����Ͷ�λֹˮ��ʱ��Ӧע�⽽���ij�����������������������������ֹˮ���������������������Ӧ��ʱ���������ڽӷ���κ���ˮѹʱ��ֹˮ���ֿ������������ͻ����ȡ��̶�ֹˮ��ʱ��ֻ����ֹˮ����������λ�ϴ��״���������IJ��֡��ڶ�λ��ֹˮ��ʱ��һ��Ҫʹ���ڽ��沿

��ˮ������ֹˮ������

���dz�˵���Ƽ��ı�������Ƽ�Ҳ�ڸı��š����꣬Խ��Խ��Ŀ�ѧ��Ϣ�������õ��У����ǻۡ��ѳ�Ϊ����Ĵ����ʡ�ÿ�괺�ڻؼҵĽ�ͨ���߲�������������ɻ�������ȴ�������м۸�Ҳ�������Ľ�ͨ���ߡ����գ���·����˾����������ʾ��2��2�գ����³������������Ϊ��40��ģ��Ѿ����˷��Ǻ�߷�ʱ�Ρ������겻ͬ���ǣ����꣬���ٳ�վ�������ˡ��������ô�ҳ��и���ݡ��������ܻ����ˣ����ɣ�ָ·�������������ǣ������ˡ�С贡���Ϊ������վ�����ڱ�վ�����ǡ�������վ��������վ��������������ܣ�ͨ������ֲ��������ݿ��д洢�˴�����·��Ϣ�����ҵ�����ݣ�����������վ�ڵ�������վ������Ϣ����վ�г�ʱ�̡��г�ͣ��վ���г�������Ϣ����·���Ρ�վ�ڷ����ѯ�⣬�������������������صĵ�����Ϣ�����������������Ϣ������������ˡ�С贡��������Իش��ÿ��й�������ѯ��ͬʱ����Ӧ�ÿ�Ҫ���˱��ݻ����˸��衣�����ˡ�С贡����˽⣬���꣬������վ�����ڱ�վ�������Ƴ�11̨���ܻ����ˣ�����ѯ����Խ��Խ���ܻ�����Ϣ���������һ���ֲ�ϰ��ʹ�û�������ѯ���ÿͣ���·���Ż�ר�����������ɸ��˹�����㣬�������ܻ�����ͬʱ�����ÿ���ѯ��ȷ���������ġ�

Rubber waterstop construction matters needing attention in the construction process, because there are many sharp corners and sharp stone reinforced concrete, so in the pouring and itioning of the waterstop, should pay attention to the impact of casting, so as to oid the excess force piercing the rubber sealing belt. If it is found that the rupture phenomenon should be repaired in time, otherwise, in the joint deformation and water pressure, the ability of rubber waterproof belt to resist external force will be greatly reduced. When fixing the water stop belt, the hole can be punched and punched on the allowable part of the water stopping belt, and the part of the body can not be damaged. When locating the rubber stop, make sure it is at the interface

λ����ƽչ����������ֹˮ��������Ť�ᣬ�緢����Ť�չ����Ӧ��ʱ�����ڽ�ע�̶�ֹˮ��ʱ��Ӧ��ֹֹˮ��ƫ�ƣ����ⵥ�����̣�Ӱ��ֹˮЧ�����ڻ���������ʱ��������������ֹˮ���ͻ�������ϲ�����Ӱ��ֹˮЧ����ֹˮ����ͷ����ճ�����ã���ʩ���ֳ������߱����ɲ�������

Keep a flat, but can not let the strip rolling and kink, if there is no kink like show should be adjusted in time in the casting and fixing strip, waterstop deviation shall be prevented so as not to affect the sealing effect of unilateral shortened. The concrete must be fully shake when pouring and tamping, so as to oid the bad combination of the water stop and the concrete and affect the sealing effect. The joint of the water stop belt must be well bonded, such as hot sulfur, if the construction site conditions are ailable

��һƪ��http://www.cntrades.com/member/http://www.cntrades.com/b2b/hsxingyv/news/itemid-3570701.html